What is an Industrial Water-Based Cooling System and How Does it Work?

Water-based cooling systems, also known as hydronic cooling systems, are a type of heating, ventilation and air conditioning (HVAC) system that use water to transfer heat from one location to another. Hydronic systems can either heat or cool buildings, in fact. The systems operate by either absorbing heat inside the building and transferring it outside to cool the building, or vice versa, absorbing heat from outside air and bringing it inside.

There are several different types of water-based cooling systems, including:

- Closed-loop systems: These systems use a closed loop of water to transfer heat between the building and the outside environment. The water is pumped through a series of pipes, and heat is transferred to or from the water via a heat exchanger.

- Open-loop systems: These systems use a natural body of water, such as a river or lake, as the heat source or sink. Heat is transferred to or from the water via a heat exchanger.

- Evaporative cooling systems: These systems use the evaporation of water to cool the air. Hot, dry air is passed over a wet surface, such as a wet pad or mist, and the water evaporates, absorbing heat from the air in the process.

Water-based cooling systems offer several advantages over other types of cooling systems. They are typically more energy efficient than air-based systems, as water has a higher thermal capacity than air and can more effectively transfer heat. They are also more durable and require less maintenance, as they do not have moving parts such as fans or compressors. In addition, the lack of fans means less air movement, which can help improve air quality and reduce the introduction or spread of allergens.

Hydronic cooling systems, also known as radiant cooling systems, do not require ductwork like traditional forced-air systems do. This can be an advantage in commercial buildings because it eliminates the need for space to accommodate ductwork which can save on construction costs and allow for greater flexibility in building design.

Within a closed loop system, the water does not require frequent changes, unlike refrigerants in air-based systems, again saving time and money. Hydronic cooling systems pose a more environmentally friendly option than an air-based system. For one, because they don’t rely on the ozone-depleting refrigerants within an air-based system. Secondly, because hydronic systems rely on water as a coolant, the design can utilize greywater or rainwater as the water source. This conserves resources while reducing costs.

Another advantage of hydronic cooling systems is their flexibility in terms of design. A hydronic system can cool specific areas within a building, rather than the entire facility. This zone control can help save energy and money. This type of cooling system can be integrated into existing HVAC systems, posing a viable option when renovating an older structure.

Within a closed loop system, the water does not require frequent changes, unlike the maintenance required by refrigerants in air-based systems. Hydronic cooling also presents one of the most environmentally friendly options for an HVAC system. It doesn’t rely on ozone-depleting refrigerants in an air-based system, as mentioned. Secondly, because hydronic systems rely on water as a coolant, system design can utilize greywater or rainwater, to conserve resources while reducing costs.

This design flexibility extends to zone heating and cooling. A hydronic system can regulate temperatures in specific areas within a building, rather than the entire facility, to help save energy and money. This type of cooling system can be integrated into existing HVAC systems, a consideration when renovating an older or existing structure.

However, water-based cooling systems can be more complex to install and maintain than air-based systems, and they require a reliable source of water and a way to dispose of the wastewater. They also may not be suitable for climates with very low humidity, as the evaporative cooling process is less effective in dry air.

Maintenance Recommendations For Hydronic Closed-Loop Water Systems

Even a closed loop hydronic cooling system requires regular maintenance or treatments to keep it running at peak efficiencies. It also pays to avoid issues with piping and components which are susceptible to corrosion. One type of corrosion stems from the buildup of magnetite. Magnetite is a type of magnetic particle that develops within closed loop systems when iron is present, and oxygen is not.

Over time, iron pipes form a magnetite layer and particles will circulate through the water system. This makes heat exchangers susceptible to fouling. Even the tiniest amount of fouling, as small as 1/100th of an inch, can reduce the system’s efficiency by 10%.

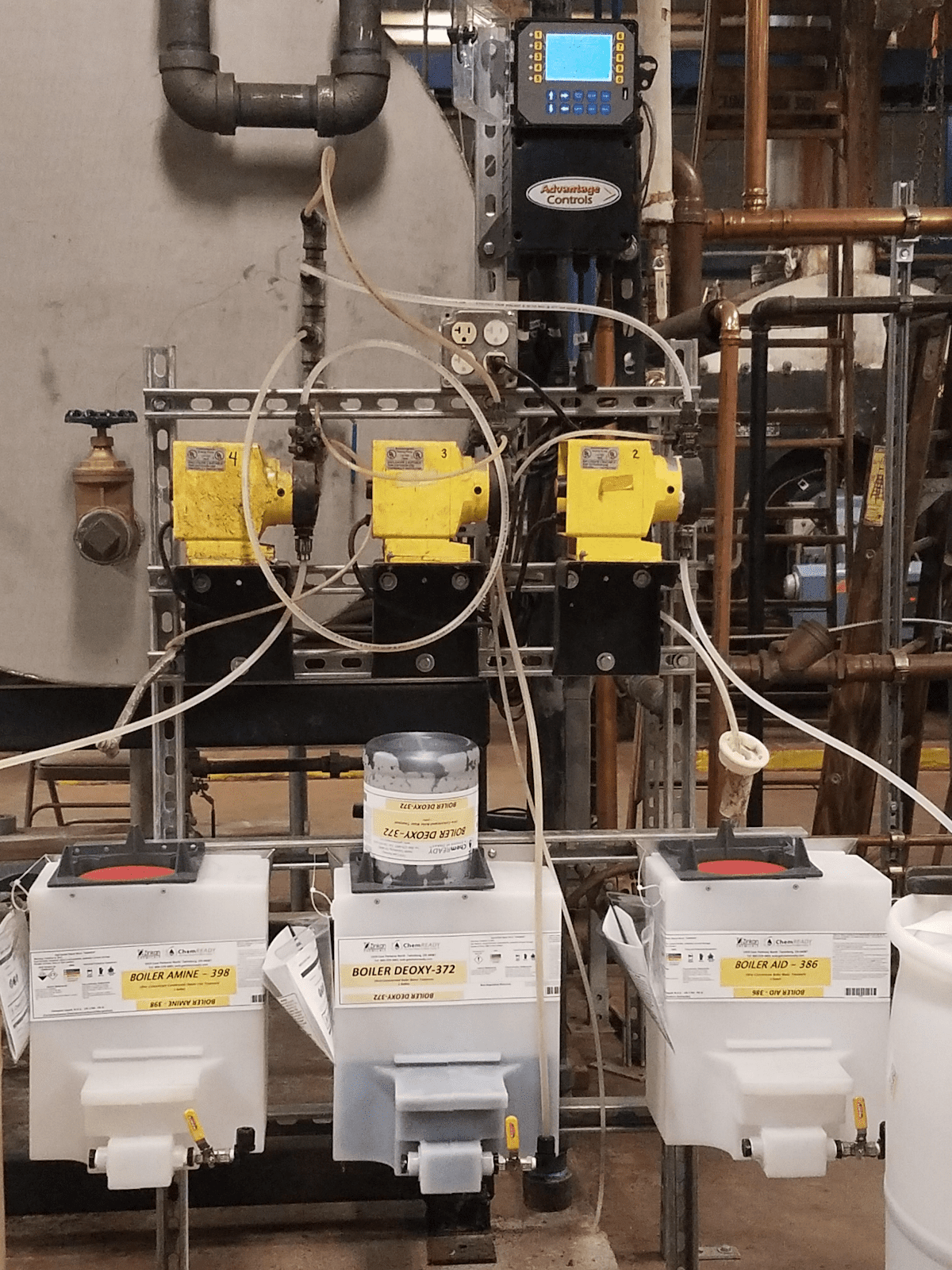

ChemREADY offers treatments for hydronic water systems such as closed loop, to maintain a proper chemical balance and to remove the magnetite. Its MagStrainer™ magnetic water filter, prevents fouling through sidestream or inline installation. Other closed loop water system treatments can include flushing, checking and replacing worn filters, monitoring water levels and testing pH.

Overall, water-based cooling systems can be an effective and efficient way to cool buildings, but they may not be the best choice for every application. It is important to carefully consider the specific needs and constraints of a building and its location when deciding whether a water-based cooling system is the right choice.

Hydronic cooling systems, even the closed loop variety, are far from a “set it and forget it” component of HVAC equipment. Find a trusted partner with the right experience and tools to help manage and maintain hydronic cooling systems. Ask ChemREADY about proper chemical treatments, our maintenance programs for hydronic cooling systems, or our proprietary MagStrainer magnetic water filter. Maintain the efficiency of your hydronic water filter, prevent fouling and lengthen the service life of your HVAC equipment with a call to ChemREADY.