Matec’s Concrete Water Recycling (CWR) plants are engineered to remove solids from water used to wash ready mix trucks, cement mixers, pumps, and construction equipment. When paired with Disol 5000 (grease trap), these plants also handle water runoff from cleaning truck wheels and tires, addressing construction site needs comprehensively.

Designed to recover and reuse water automatically, Matec’s CWR plants filter solids without requiring chemical additives. This innovative approach provides a manageable solid output, eliminating the hassle of cleaning weir pits while recovering aggregates like sand and stone for immediate reuse.

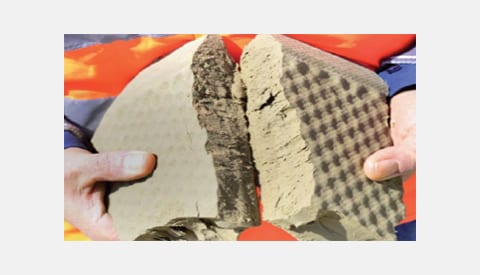

Using Matec CWR plants, operations can optimize their processes by handling return concrete efficiently without dumping, drying, or crushing. Sand and stone are immediately recoverable, and customizable separation ensures optimal use of recovered materials.

Matec’s concrete water recycling plants are a versatile solution for industries dealing with concrete washout slurry. Whether for ready mix operations, concrete cutting, or precast applications, these plants handle it all while improving operational efficiency and sustainability.

Contact ChemREADY today to explore how Matec CWR plants can transform your water management processes and help you achieve cost savings, compliance, and sustainability.

A Matec CWR plant removes solids from water used in concrete operations, such as washing ready mix trucks and cement mixers. It reclaims up to 95% of water for reuse, reduces waste, and provides manageable dry sludge for disposal.

Matec CWR plants recover sand, stone, and cement from washout slurry. These materials are separated and ready for immediate reuse, improving sustainability and reducing waste.

By reclaiming water and aggregates, Matec CWR plants minimize water purchases and waste disposal costs. Their automated design reduces labor and operational costs while eliminating the need for weir pit cleaning.

Yes, Matec CWR plants can be enclosed for cold-weather operations, ensuring consistent performance in all climates.

Matec CWR plants are ideal for ready mix operations, concrete cutting, precast, pipe lining, and any industry dealing with concrete washout slurry.