The Basics of Mining Wastewater Treatment

Wastewater treatment is critical for mining applications. Used in mineral processing to recover valuable metals from ore, water is essential to the mining industry. However, using water in this way causes mineral contaminants and other solids to accumulate in your process water supply. This leads to contaminated mining wastewater that cannot be reused or returned into the environment due to community health concerns and environmental regulations without treatment. As such, mining operations need to have a consistent and reliable source of clean water to keep business running.

Wastewater treatment is critical for mining applications. Used in mineral processing to recover valuable metals from ore, water is essential to the mining industry. However, using water in this way causes mineral contaminants and other solids to accumulate in your process water supply. This leads to contaminated mining wastewater that cannot be reused or returned into the environment due to community health concerns and environmental regulations without treatment. As such, mining operations need to have a consistent and reliable source of clean water to keep business running.

While some mining operations may choose to pay an outside company to transport the wastewater, hauling waste sludge is inefficient and costly. Retention ponds are also an option, but they lose their effectiveness over time as they become dirtier, leading to a bad Return-on-Investment (ROI). Instead, treating the water on-site with chemicals and filtration methods can lead to several benefits, including:

- Significant cost savings

- Full control of the treatment process and long-term sustainability

- The ability to reuse the water once treated

- Maximum water recovery with a near closed-loop solution

This is especially true now with the increase in demand for lithium and other metals used in electronics and energy storage. Water and energy challenges need to be handled head-on to ensure that this demand is met with profitable and energy-efficient mining operations.

Calculate Your Mining and Dewatering ROI

The Problem with Mining Wastewater

While necessary for mineral processing, that basics of mining wastewater treatment dealing with water that meets ore and other sediment causes parts of the rock to leach into the process water. The acidity of the water will then rise as increasing amounts of metal and sulfates contaminate the water.

This process creates what’s known as mining-influenced water (MIW), which is defined as any water that’s been chemically affected by mining or mineral processing. The biggest issues with mining-influenced water include:

- Acid mine drainage

- Processing chemicals pollution

- Heavy metal contamination and leaching

- Sedimentation and erosion

Any of the problems can cause your water to fail to maintain regulatory standards, forcing you to treat it or dispose of the wastewater properly.

Why Do I Need To Treat My Mining Wastewater?

Without proper wastewater treatment, there are several water-related challenges that can ruin a mining site’s efficacy. This is because mining wastewater and the tailings that the industry produces are often very acidic and high in suspended solids.

Problems that persist in uncontrolled mining applications include:

- Acid runoff from mine drainage and tailings piles

- Groundwater contamination

- Highly saline waste

- Aquifer toxification

These issues are intensified due to many otherwise profitable mine-mills being in areas with already-stressed water supplies. Mining activities in these places further degrade what little fresh water there is.

From both an environmental and operational standpoint, the best course of action is to prevent contamination to outside water sources and safely reuse mining wastewater as much as possible. Fortunately, through advanced wastewater treatment solutions, you can reuse mining wastewater for mining, irrigation and even drinking water.

How Water Treatment Works for Mining Operations

When it comes to water treatment for mining operations, the focus is treating process water. However, water associated with mine drainage and stormwater is also important to treat if you want to maximize water efficiencies.

No matter which water source you’re treating, the primary goals are to remove metals, solids, and other contaminants from the water, as well as restore the water to optimal pH levels. Treating your mining wastewater requires a combination of chemicals and mechanical filtration.

pH Adjusters

One of the first things that you need to do when treating mining wastewater is to restore optimal pH levels to the water. Not only is this important in and of itself to maintain the quality of your water, but it will also help dissolved metals to precipitate. By raising the pH of the water, positively charged metal ions will react with negatively-charged hydroxide ions. This results in a dense and insoluble metal particle that’s easier to work with.

Used in the right amounts, pH adjusters can help to lower your mining wastewater’s acidity, returning it to more balanced pH levels. While a pH of 7 is technically neutral, it’s best to restore your mining water to a pH of 8 or more before continuing on with other treatment methods.

Coagulants and Flocculants

After getting your water’s pH levels right, you can use coagulants and flocculants to take the small metal particles and suspended solids in your water and combine them into larger clumps. This makes them easier to filter out and remove by mechanical means.

Formulated for a wide range of mineral processing applications, ChemREADY’s high-quality line of FlocREADY flocculants and coagulants are designed to improve mining wastewater treatment and lower overall costs.

Additional Chemicals

While pH adjusters, coagulants and flocculants are the main chemicals used to mining wastewater treatment, certain applications require additional chemicals to protect your systems or to help prepare your water for filtration. These can include:

- Water softeners and ion exchangers

- Corrosion inhibitors

- Algaecides and biocides

Filtration

Once you’ve optimized the quality of your water with the right chemicals, mechanical filtration methods can remove any suspended particles and certain types of organic matter. While there are a few different machines to use, the main types of mechanical filtration equipment are:

- Centrifuges

- Filter Presses

- Belt Presses

What Are Some Solutions for Treating Wastewater from the Mining Industry?

Since mining wastewater can be highly variable, different treatment solutions and methods of mechanical filtration exist. While some equipment is better than others in most cases, each solution has a place in the right application.

Full Range of Wastewater Treatment Technologies include: Biological Processes, Desalination, Clarification, Evaporation & Crystallization, Disinfection, Filtration, Ion Exchange, Membrane Separation, Package Plants, Sludge Dewatering & Handling, and Zero Liquid Discharge.

What Are Methods of Dewatering Mining Wastewater?

For Sludge Dewatering, here are the top wastewater treatment technologies for the mining industry:

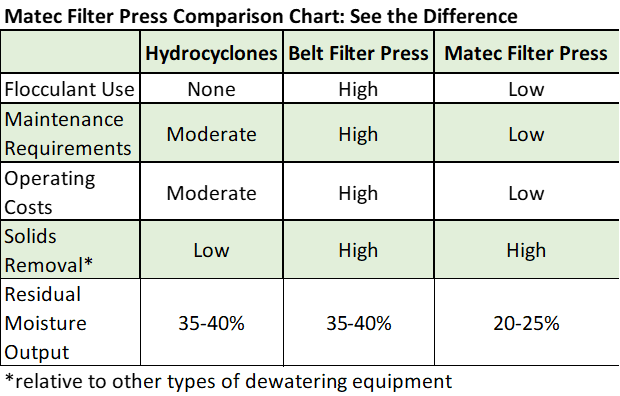

Hydrocyclones

Rather common in the industry, hydrocyclones are used in many different mining applications for classification, fines recovery and dewatering. They are great at solids removal considering that they do not have any moving parts and that you do not need to add any chemicals, making them a simple and cost-effective solution. You can also process high volumes of wastewater without taking up a lot of floor space.

Hydrocyclones are built around using centrifugal forces to remove solids from your water. The basic design of a hydrocyclone includes an upper feed section, with either a tangential or involute style feed inlet, followed by a series of lower conical sections, and finally ending with the apex or spigot at the bottom of the device.

The main issue with hydrocyclones is that they are not equipped to be a complete solids removal solution all by themselves. For total solids removal, you will need to employ another means of wastewater treatment as well, like a high-efficiency filter press. However, hydrocyclones will allow you to remove a significant number of solids and aggregate prior to your primary method of wastewater treatment, offering an overall better process.

Belt Filters

Compared to other wastewater equipment, belt filters can be set up and shut down rather quickly, without a lot of initial capital and resources required. As such, they are commonly used for the mechanical dewatering of mining wastewater to keep costs low with a smaller footprint.

Belt presses work by dewatering a slurry between two moving belts held under tension, as the water runs over and under a series of rollers. This produces a clump of solids known as a “cake” for easy removal.

Basic designs feature a polymer conditioning area, gravity drainage zones and low- and high-pressure squeezing zones. For better solids removal, you can add larger filtration areas, variable belt speeds, and additional rollers.

While belt filters are easy and cheap to get you started, they quickly become a more expensive option due to their need for high doses of chemical flocculants. On tap of that, replacing the belt can also be very costly and frequent. The cakes you get from a belt press will also often need further processing before dry stacking.

Filter Presses

No matter what industry or application you’re talking about, the filter press is the gold standard when it comes to wastewater treatment and solids removal.

Filter press operations revolve around filter plates. In normal operation, a pump pushes a slurry through the device’s chambers, which are made of filter plates. These plates remove solids from your mining wastewater and allow you to return clean water back into your systems.

As one of the oldest pieces of dewatering equipment available, the humble filter press has had years upon years of improvements that you get to take advantage of. In fact, filter presses typically offer higher energy efficiencies than other pieces of dewatering equipment, with 1/6th the total operating cost of a belt press or centrifuge.

For mining applications, there are both low- and high-pressure filter presses used today. However, low-pressure filter presses usually are not as efficient or cost-productive, requiring more complex designs that carry a higher maintenance burden. That is why most mine-mills will choose a high-pressure option.

The Best High-Pressure Filter Press Available

For highly efficient mining operations, ChemREADY offers the high-pressure Matec® filter press. With a well-engineered design, these filter presses operate under pressures of up to 30 bar to handle even the most solids-laden slurries.

Matec filter presses also use very few flocculants and require less maintenance than other systems. Their cakes are highly stable and stackable cakes, allowing for easy tailings discharge without the need for further processing.

The Matec filter press improves upon typical filter presses, offering:

- Automatic washing and an open filtrate design

- Real-time remote monitoring and assistance

- High-pressure technology (HPT) that works at over 30 bar

- Simple and easy cake discharge

How ChemREADY Can Help

With significant experience in water treatment for mining operations, ChemREADY is your perfect partner for the basics of mining wastewater treatment. We’re more than just a chemical supplier – our industry-proven experts are here to help you every step of the way.

While most suppliers will just try to throw a standard assortment of chemicals at your problem and hope that it works, ChemREADY does it right. Our experts will spend time analyzing your water to determine what chemicals to use and in what quantities. The cost-benefit of our risk analysis provides significant savings to you in the long run, allowing you to future-proof your water treatment process.

If you want to learn more about how we can help with your mining wastewater treatment, or you’d like to discuss your needs in detail, contact the ChemREADY team today.

Need some expert advice or repair services? Contact ChemREADY today to schedule your free consultation.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.