How Water Treatment Chemicals Maintain Cooling Tower Efficiency

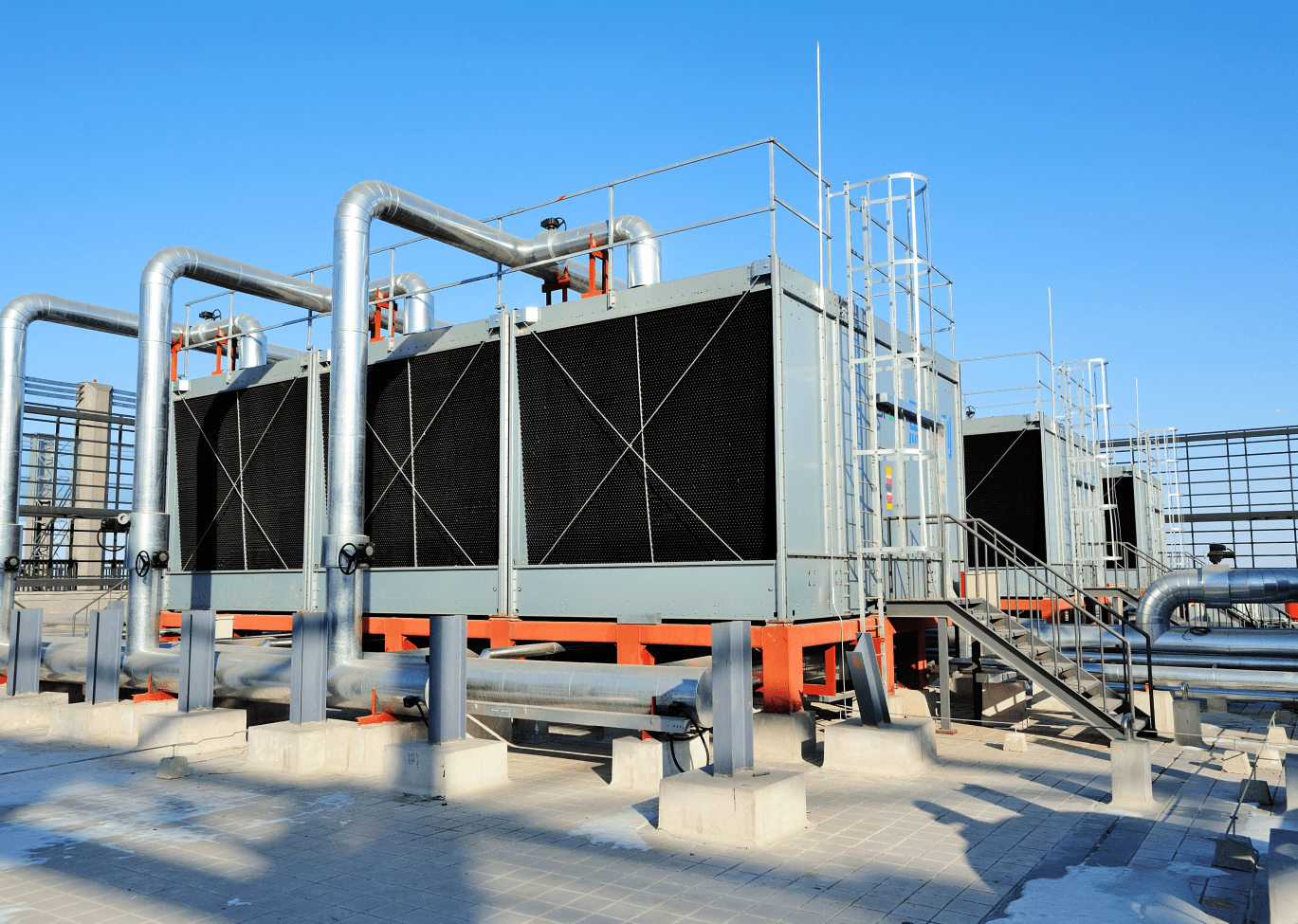

Cooling towers are essential components of many industrial and commercial facilities. These systems utilize the heat exchange process to efficiently cool water. Cooling tower sizes vary depending on the size of the facility it serves and the building’s needs, with wide variance between the cooling towers serving oil refineries or power plants for example, compared to a medical facility or residential building.

However, what these facilities all have in common is that the water used in cooling towers can become contaminated with bacteria, algae, and other impurities, which can lead to a variety of problems. Best practices dictate that facilities which use cooling tower treatment chemicals to prevent these issues can keep their systems running smoothly and efficiently. This blog will discuss the benefits of cooling towers efficiency, typical contaminants that can impact cooling towers, the types of water treatment chemicals used, and important considerations for effective water treatment.

Untreated Cooling Towers: A Breeding Ground For Water Issues

Cooling towers are ubiquitous in almost every industry, commercial building, residential facilities and medical centers, that need efficient heat exchange. Hot water is circulated within the tower structure and cooled by air moving inside it; as the hot liquid passes through the walls its temperature decreased, making it much cooler when it returns to the system.

The water upon which this system depends can cause several problems if left untreated however, which can range from mild to severe, up to and including damaging the cooling tower itself to the point of requiring a complete replacement. These issues include bacterial contamination, fouling and scale.

First, the water, when subjected to heat, presents an ideal breeding ground for Legionella heat-loving bacteria to grow. A second issue, fouling, occurs from the presence and buildup of bacteria, fungi and algae. These slime-like biofilms adhere to surfaces within the cooling tower, which negatively impact the tower’s heat transfer capabilities. Finally, scale builds up from hard minerals present in the source water supply, which can lead to corrosion and decreased system efficiency.

Chemicals Used To Treat Bacteria, Fouling And Scale

There are several types of chemicals that are commonly used in the treatment of cooling towers. These include biocides, scale inhibitors, corrosion inhibitors, and pH adjusters. Let’s take a closer look at each of these types of chemicals and how they can help to maintain the health and effectiveness of a cooling tower system.

Biocides are chemicals that are used to kill or inhibit the growth of bacteria, algae, and other microorganisms in the water used in cooling towers. These chemicals are often used in conjunction with other types of treatment chemicals to keep the water clean and free of contaminants. Some common biocides that are used in cooling tower treatment include chlorine, bromine, and quaternary ammonium compounds.

Scale inhibitors are chemicals that are used to prevent the formation of scale, which is a hard, crystalline deposit that can form on the surfaces of pipes and other equipment in a cooling tower system. Scale can reduce the efficiency of the system and cause serious problems if it is not properly controlled. Some common scale inhibitors that are used in cooling tower treatment include phosphonates, polymers, and acrylates.

Corrosion inhibitors are chemicals that are used to protect the metal surfaces of a cooling tower system from corrosion. These chemicals work by forming a protective film on the metal surfaces that helps to prevent the chemical reactions that can lead to corrosion. Some common corrosion inhibitors that are used in cooling tower treatment include amines, phosphates, and polymers.

pH adjusters are chemicals that are used to regulate the pH of the water in a cooling tower system. The pH of the water can affect the effectiveness of other treatment chemicals and can also contribute to the formation of scale and corrosion. Some common pH adjusters that are used in cooling tower treatment include acid, base, and buffer solutions.

Water Treatment With ChemREADY

A proper water treatment regimen begins with regular monitoring and testing to prevent these problems from taking hold within a cooling tower, to prevent scale formation, corrosion and biological growth. Testing service from ChemREADY offers a comprehensive line of chemical products for water treatment and can devise a plan for your equipment and facility. A complete list and description of our chemical types can be found here. Our technicians will determine the proper dosing and application procedures. Determining dosage amounts helps avoid excess spending and chemical usage, to prevent environmental consequences.

Proper treatment can also help to extend the life of the system and save money on maintenance and repairs. It is also important to follow the manufacturer’s instructions and safety precautions when using these chemicals to ensure their safe and effective use. A balanced chemical treatment plan helps reduce overall operational costs and maintenance issues and extends the lifespan of costly capital equipment. Talk to the experts at ChemREADY today to ask about the products best suited for your water systems, to reduce the risk of corrosion, fouling and scaling.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.