What is a Deep Cone Water Clarifier?

Deep Cone Water Clarifier, or decanter clarifiers, are a type of vertical thickener used in the clarifier wastewater treatment process. Unlike the filtration carried out by the filter press, the clarification is a continuous process that separates water from the solid particles suspended into it. Matec can provide customers with any type of decanters, by designing and manufacturing vertical and horizontal ones made of stainless steel or concrete.

Did you know Deep Cone Clarifiers are free of maintenance? Our Matec Deep Cone Water Clarifier has no moving parts, rake systems, suction, or pumping mechanics. As a matter of fact, they are the most efficient wastewater clarifiers in the industry today!

How Deep Cone Water Clarifiers Work:

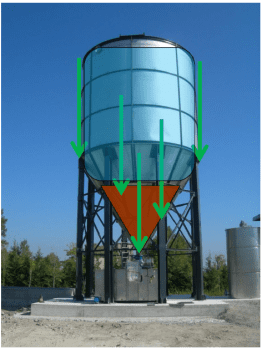

The Matec vertical decanters are based on the principle of static decantation and the natural precipitation of suspended solid particles. While decantation occurs, the solid particles sink down to the bottom of the structure. During this, the clean water overflows into the drainage system at the top and discharges in a clean water tank or pit.

When adding the flocculant, the sedimentation of the sludge at the bottom of the silo speeds up, simultaneously while the custom design and dimensions create a water column. Then this presses over the sludge and guarantees the correct thickness of the mud.

Matec develops the shape of the vertical decanter, the proportion between the cone, and the upper cylinder based off years of experience in waste water filtration.

Consequently, the cone’s inclination degree perfects the thickening of the mud. Also, the upper cylinder can also be used as an extra stocking space.

Deep Cone Clarification Benefits:

- Thick mud (we arrive at 50%-55% of solids)

- Reduces costs for concrete basement

- EXTRA STOCK FOR MUD

- Highest performance per unit area for depuration

- Lowest operating cost ever, also for flocculant consumption

- Fewest parts – all NON moving as well

- NO suction pump (no further Kw consumption)

- NO maintenance costs

- Combines thickening and clarification

- Ingenious design which guarantees small forces

- Turnkey projects with best delivery times

Learn about how Deep Cone Clarification differs from Rake Style Clarifiers: Deep Cone Vs. Rake Style Clarifiers

Deep Cone Water Clarifier Parts:

Available Materials for Internal Parts

- Structural or Stainless Steel

- Lightweight or Steel Paint

- We paint Components to Customer Specifications

- Our Silo does NOT NEED ANY rubber-lining

Mixing Chamber

The mixing chamber is a cylindrical pipe that suspends in the center of the tank at the top. Feeding enters the mixing chamber through a T-piece manifold with 45° outlet bends, each facing 30° down, providing good mixing and dispersion of flocculant which adds directly into the mixing chamber as well. Feeding particles will exit the bottom of the mixing chamber achieving total flocculation.

Overflow Drainage Channel

The overflow launder has V- notches cut all round. Additionally, its height is adjustable, and it is put between the mixing chamber and the vertical side of the THICKNER.

How the Clarification Water Treatment Cycle Works:

- Water from the washing of aggregates, cutting of marble, or any other process is driven to the wastewater collection tank, which is made of concrete to your specifications. As a result, the tank collects all the water for purification.

- From the collection tank, the Pemo vertical or submersible pump sends the water to the static decanters, whose capacity depends on the water flow/minute according to the hydraulic separation principle.

- Based off how much slurry the water contains, the automatic metering system (automatic preparation of the polyelectrolyte) measures out and lets in the correct amount of flocculant (polyelectrolyte).

- The water pumps into the slurry decanter and the slurry precipitates under the effect of the flocculant to the bottom of the cone.

- The purified water overflows into the well and falls back into the freshwater tank, pure and ready to use in production.

- The slurry that settles in the decanters then falls through the automatically opening pneumatic valve (normally closed) into the steel tank below, to be homogenized.

Pressure Drives the Flow:

We have thick mud for two reasons:

- Pressure of water column on the mud stacks in the cone (1-1,5 BAR)

- Geometrical drawing of decanter/cone

Because of this, the result is 3 zones of settling – clean water on the top, active settling in the middle and concentrates mud at the bottom.

With the opening of the discharge valve, the mud easily moves to your filter press for further dewatering.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.