Plate & Frame Filter Press vs. Belt Press

Did you know that plate and frame presses have made major strides in the dewatering industry? Much further along than the old belt press style dewatering process. Newer plate and frame presses can provide an enormous annual cost savings. These savings come from multiple sources within the process and are quite significant when added up. On average, a Belt Press can cost the owner 6.5 times as much to operate annually than a Filter Press yielding over $100,000 for every 20 Tons Per Hour produced.

In this Water Facts, we will review and discuss some of the areas of a Filter Press vs. Belt Press differ and what this means to you as an Owner.

Unlike their counterpart, plate and frame presses no longer require flocculants to be used inside the press. So, Filter Press vs. Belt Press, the polyelectrolyte is still used in the clarification process, but is very minimal, such as in a thickener, usually only using 0.2 kilograms per ton.Two Costs to Implement Filter Press vs. Belt Press.

A typical belt press would consume approximately 0.5 kilograms per ton in just the press itself. Average polyelectrolyte cost is $2.92 per kilogram. This means you will save approximately $47,600 per year by using a Matec filter press (calculations based on 8 hour daily use).

Maintenance:

Another advantage is the maintenance required. The belt press is a much more complex machine and requires as much as 8 times the hours needed to perform maintenance on a filter press. In addition, it requires a full time dedicated operator in most situations. Using the same parameter as before, an 8 hour shift with 20 tons of output, the savings would come out to around $23,800 per year when using a Matec filter press. Add that to the flocculent savings and annually you will save around $71,400.

The Matec filter press outputs cakes at 15-20% moisture. When compared to a belt press, which is around 35%-40% moisture level, the Matec press is better by substantial margins.

What does this mean for you? The material from a belt press has larger volumes which leads to higher costs for disposal and higher hauling charges. Consequently, Matec filter press disposal costs are approximately 1/3 that of a belt press.

Lastly, there is a major difference in operator use between the two processes. The belt press requires constant attention from an operator. They can be extremely difficult to manage.

The Matec filter press on the other hand is 100% automated so there is no requirement for dedicated personnel. We only require routine maintenance to be performed weekly and requires less than 8 hours per week.

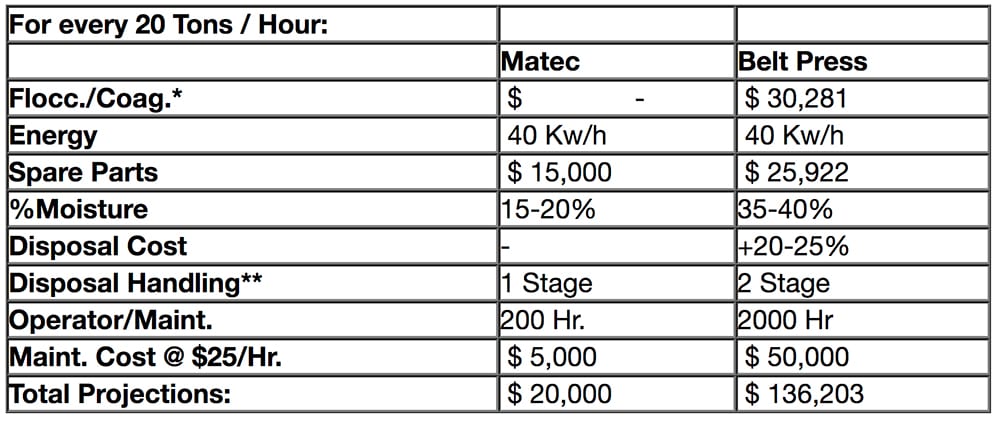

As you can tell, Filter Press vs. Belt Press, when doing a direct comparison with a filter press, the belt press is going to cost the operation much more to maintain. The following chart outlines these costs in more detail based on a 20 TPH operation. For every 20 Tons Per Hour, the operation can save over $100,000 per year.

*Assumes Flocculant is already added for Clarification Purposes.

** Matec can be directly disposed without placing the material for additional dry time, which results in 2 stages of handling. Additional handling and placement is valued at $30,000 annually based on labor rates. Matec allows the material to be conveyed once to its final destination.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.