Basics of Water Treatment for Cooling Towers

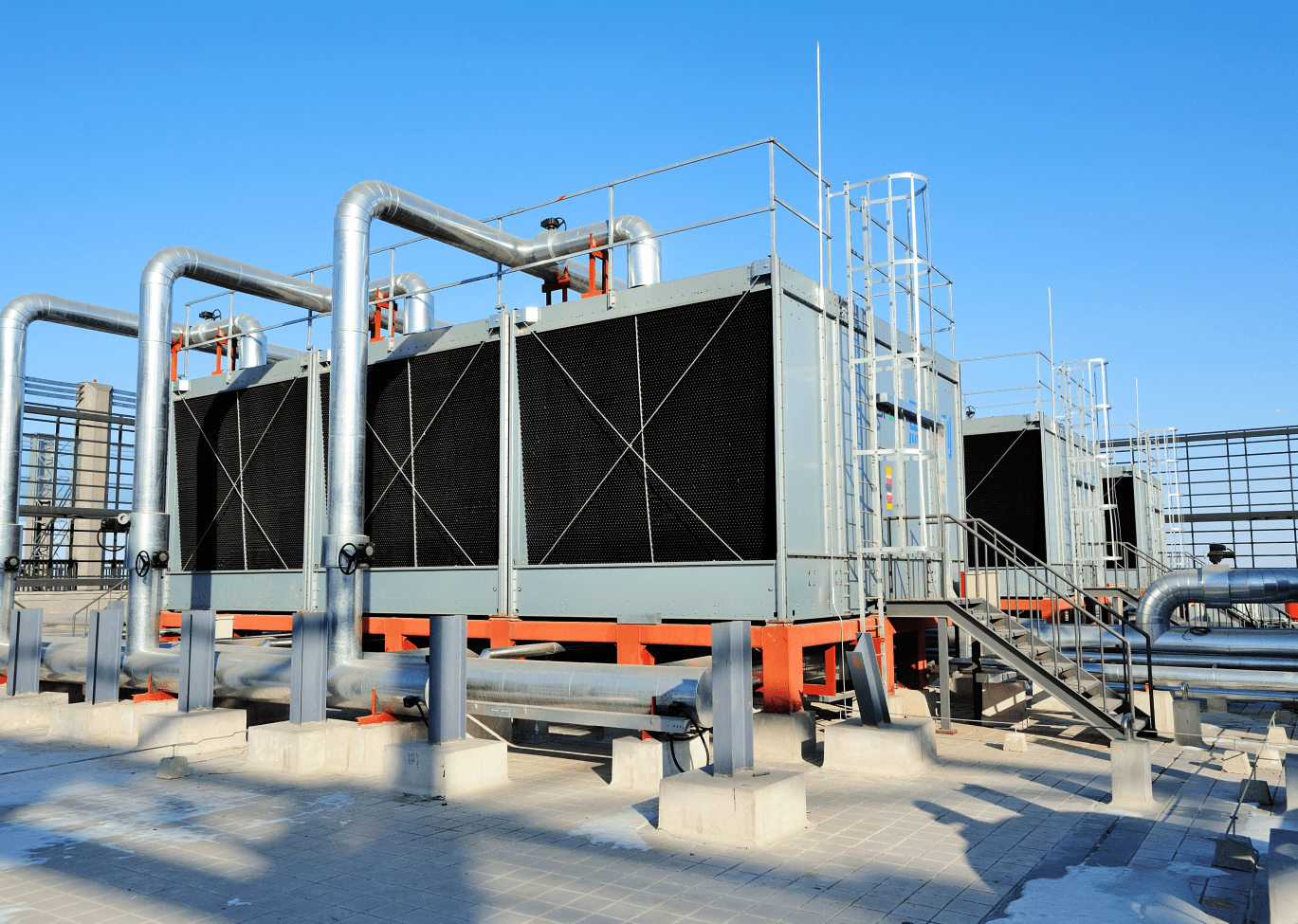

Water treatment for cooling towers is essential to maintaining efficiency, minimizing operational costs, and preventing common water-related issues such as corrosion, scaling, and microbiological buildup. Cooling towers play a critical role in removing heat from various industrial processes and buildings, making proper water treatment a necessity.

Why Is Cooling Water Treatment Necessary?

Cooling tower water treatment helps mitigate key issues that can reduce plant productivity, lead to unplanned downtime, and require costly repairs. The most common problems associated with cooling tower water include:

- Microbiological deposits (such as algae, bacteria, and fungi)

- Mud and grime accumulation

- Scale formation

- Corrosion

- Foam buildup

Addressing these issues through proper water treatment improves system efficiency, reduces maintenance costs, and extends the lifespan of cooling equipment.

Common Water Problems in Cooling Towers

Microbiological Deposits and Mud/Grime

Microbiological growth, including algae and bacteria, forms slimy deposits on heat exchange surfaces, reducing efficiency and potentially clogging cooling water pathways. If left untreated, these deposits can obstruct water and air flow, significantly increasing energy consumption and operational costs.

Scale Deposits

Scaling occurs when dissolved minerals, such as calcium sulfate and silica, precipitate and form solid deposits. These deposits restrict heat transfer, reducing cooling efficiency and increasing energy costs. Controlling scaling is crucial for maintaining the performance of a cooling system.

Corrosion

Corrosion occurs when cooling water comes into contact with metal components, particularly when the water contains high levels of dissolved oxygen and electrolytes. If not properly treated, corrosion can damage equipment, leading to expensive repairs or replacements.

Foam Formation

Foam can occur due to cascading water in cooling towers, potentially causing water loss, fouling, and operational inefficiencies. Foam also concentrates scale-forming materials, increasing the risk of deposits.

Cooling Tower Water Treatment Methods

1. Treating Makeup Water

Makeup water replenishes losses due to evaporation and leaks in a cooling system. Treating makeup water can involve removing hardness, adjusting pH levels, and using water softeners to prevent scale formation.

2. Filtration

Filtration removes suspended solids and organic matter that contribute to fouling, scaling, and corrosion. Proper filtration ensures optimal performance of downstream water treatment processes.

3. Chemical Treatment

Chemicals help maintain water quality and prevent issues such as scale, corrosion, and microbial growth. The most common cooling tower treatment chemicals include:

- Water softeners and ion exchangers – Prevent mineral buildup

- Corrosion inhibitors and scale inhibitors – Protect metal surfaces and prevent scaling

- Algaecides and biocides – Control microbiological growth

- Anti-foaming agents – Reduce foam formation

- pH adjusters – Maintain optimal pH levels

Automated chemical feed systems with real-time monitoring optimize chemical dosing, reducing chemical waste and operational costs.

4. Side-Stream Filtration

Side-stream filtration continuously filters a small percentage of circulating cooling water to remove drift contamination, process leaks, and suspended solids. This improves water quality, reduces fouling, and enhances overall cooling system performance.

The ChemREADY Advantage

ChemREADY provides comprehensive water treatment solutions for cooling towers, offering high-quality treatment chemicals and expert consultation services. Our approach ensures that your cooling system remains efficient, cost-effective, and compliant with industry standards.

Our Services Include:

- Site evaluations and system analysis

- Custom chemical treatment programs

- Automated feed system integration

- Ongoing maintenance and support

For expert guidance on cooling tower water treatment, contact ChemREADY today to schedule a consultation.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.