Safeguarding Your Cooling Towers: The Essential Dry Lay-Up Guide

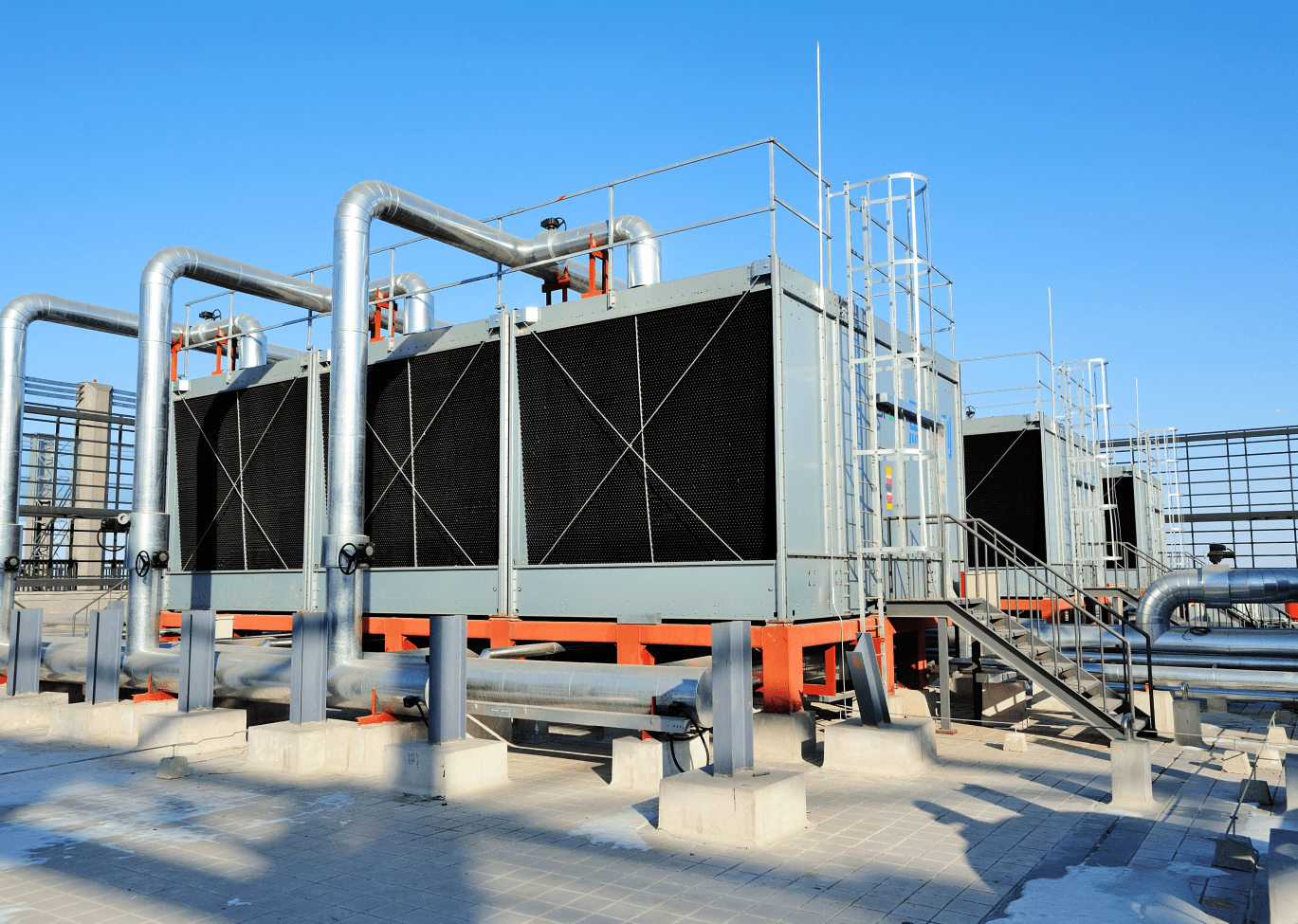

Cooling towers are vital for temperature regulation in industrial and commercial settings. When facing an extended shutdown, implementing a dry lay-up is crucial to prevent damage, control bacterial growth, and maintain overall system performance. This guide breaks down why dry lay-up matters and how to execute it effectively, ensuring your cooling towers remain in top shape for future use.

Why Dry Lay-Up Is Important

The main goal of dry lay-up is to remove all water from the system’s components—such as holding tanks, heat exchangers, and pipework—so corrosion and bacterial growth can’t take hold during downtime. Water left sitting in the system can lead to rust, scale, and microbial issues that compromise the tower’s longevity and efficiency. By draining the system and taking protective measures, you minimize costly repairs and lost productivity when it’s time to restart operations.

Step-by-Step Dry Lay-Up Procedure

-

Complete Drainage

- Thoroughly drain the cooling system, ensuring no residual water remains in any tanks, heat exchangers, or piping.

- This step is essential for eliminating the conditions that lead to corrosion and bacterial growth.

-

Corrosion Protection

- Once drained, apply a corrosion inhibitor or introduce an inert gas to blanket exposed metal surfaces.

- These measures help preserve the structural integrity of critical components until the system is back online.

-

Inspection and Cleaning

- When you restart the cooling tower, inspect the basin and other key areas for debris or potential problems.

- Remove any buildup to maintain efficient water flow and reduce contamination risks.

-

Refilling and Microbiological Control

- Refill the system with clean water, following protocols such as adding biocides or using UV disinfection to control bacteria.

- Proper microbiological management prevents system fouling and safeguards water quality.

-

Neutralizing Agent

- If you used any chemical treatments during lay-up, add a neutralizing agent to ensure safe and effective reactivation.

- This prevents chemical imbalances that can damage equipment or impact water quality.

-

Circulation and Testing

- Run water-recirculating pumps to distribute water throughout the system, opening bypass valves and verifying flow.

- Conduct water tests to confirm bacterial levels are within acceptable ranges and address any abnormalities immediately.

-

Ongoing Monitoring and Maintenance

- Closely observe the cooling tower’s performance post-restart.

- Perform additional bacteria control checks during the first week and seek guidance from your water treatment provider for any emerging issues.

Final Thoughts

A well-executed dry lay-up keeps your cooling towers in top shape during extended shutdowns, helping you avoid expensive repairs and downtime later. By draining water, protecting exposed surfaces, and following best practices for system restarts, you extend the life of your equipment and maintain efficient cooling. Remember, consistent preventive maintenance is always more cost-effective than reacting to problems once they arise.

About The Author

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.