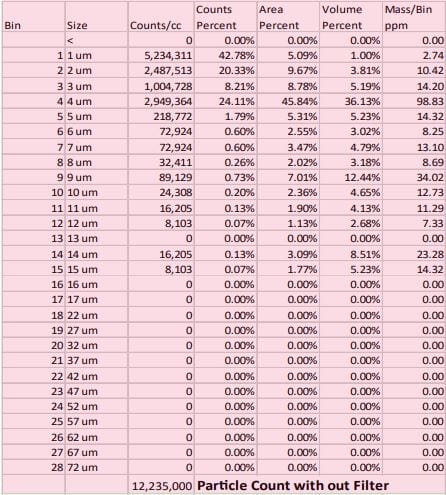

Cooling towers are integral to many industrial and commercial processes. They face challenges such as scaling, fouling, and biological growth, which can hinder performance. Implementing side stream filtration for cooling towers is an effective solution to these issues, ensuring optimal operation and longevity.

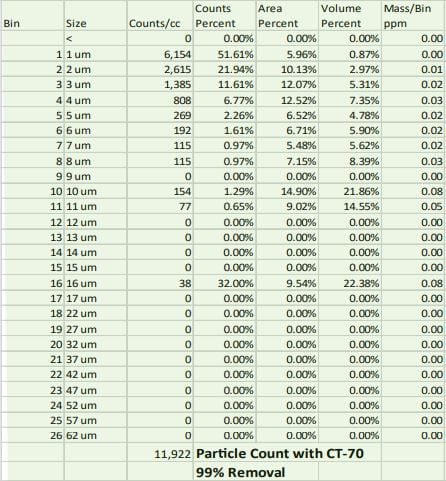

Side stream filtration continuously filters a portion of the water circulating through the cooling tower. This process helps remove suspended solids, debris, and other contaminants that cause scaling and fouling. Consequently, it maintains the efficiency of the cooling system.

Side stream filtration systems typically use a combination of mechanical filters and chemical treatments to remove impurities. The filtered water is then returned to the cooling tower, maintaining optimal water quality. These systems operate continuously, ensuring ongoing protection against contaminants. By filtering out debris and suspended solids, side stream filtration helps maintain a cleaner and more efficient cooling system.

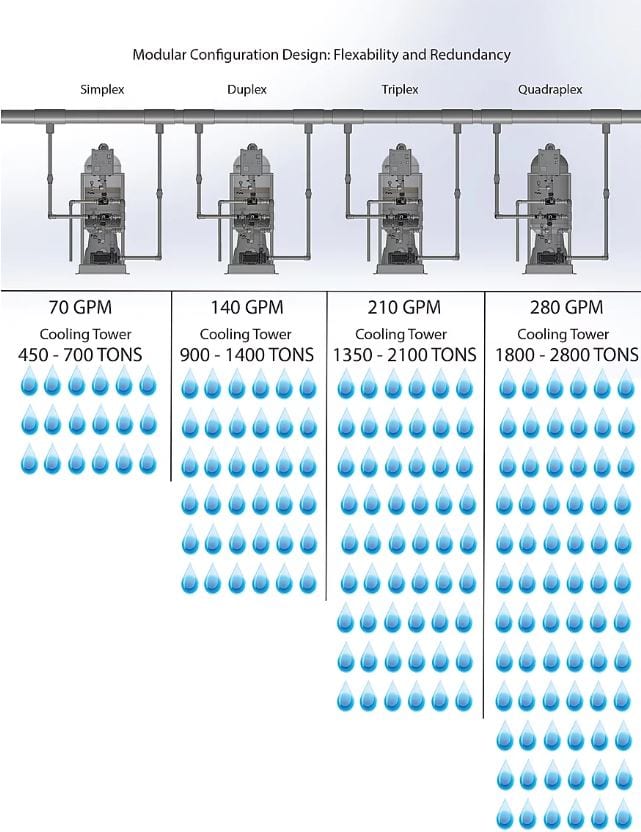

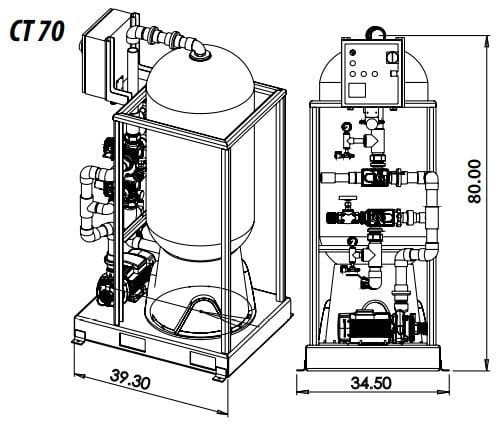

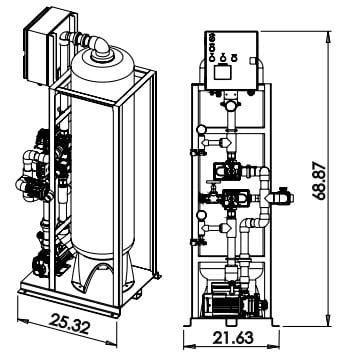

Modular Design has been used with cooling towers, boilers, air compressors, etc., for years due to flexibility and redundancy. Modularity allows for a system to be more accurately matched to the required load. If requirements increase, additional modules can be added without replacing the entire system. Conversely, if the load decreases, modules can be shut off individually and restarted without interrupting system operations.

One common misconception is that one large unit means less equipment to inspect and maintain. In reality, modular systems make maintenance more affordable and less invasive by allowing work on a single unit without shutting down the entire system. Smaller modules also mean smaller components that are easier and less costly to replace.

Modular systems often take up less space and provide greater flexibility for installation. Simply put, modularity just makes sense.

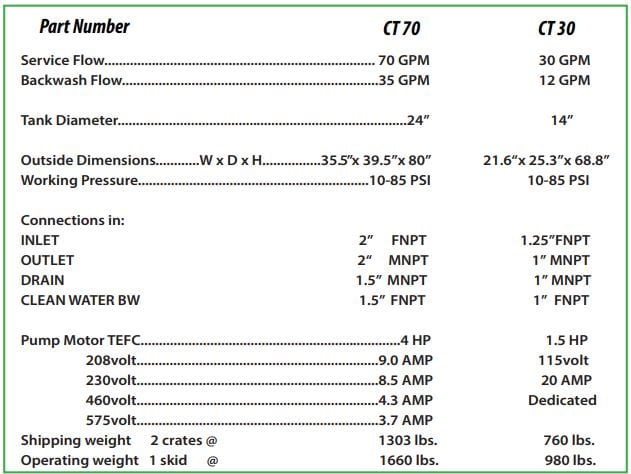

Specifications for Side Stream Cooling Tower Filtration System

When implementing side stream filtration for cooling towers, consider the following factors to ensure the system’s effectiveness:

Proper installation and operation of side stream filtration systems are critical for maximizing their benefits. Best practices include:

Side stream filtration for cooling towers is a crucial component of effective maintenance. By continuously removing contaminants, it enhances efficiency, reduces maintenance costs, and prolongs equipment life. Contact us today to learn more about improving your cooling system’s performance and longevity.

Side stream filtration for cooling towers is a crucial component of effective cooling tower maintenance. By continuously removing contaminants, it enhances efficiency, reduces maintenance costs, and prolongs equipment life. Therefore, investing in a high-quality side stream filtration system can lead to significant operational benefits and cost savings. Have questions about side stream filtration for your cooling towers? Contact us today to learn more about how we can help improve your system’s performance and longevity.

Side stream filtration is the process of continuously filtering a portion of the water circulating through a cooling tower, removing suspended solids, debris, and other contaminants that cause scaling and fouling.

By removing impurities, side stream filtration improves heat exchange efficiency, reduces energy consumption, and extends the lifespan of cooling tower components.

Modular cooling tower filters offer flexibility, easier maintenance, reduced downtime, and space-saving designs, ensuring optimal filtration and system performance.

Consider the flow rate, filter type, maintenance requirements, and compatibility with existing systems when choosing a side stream filtration system.

Modularity allows individual components to be serviced or replaced without shutting down the entire system, reducing maintenance costs and operational disruption.