Reading Time | 5 Minutes

Mining wastewater treatment keeps production steady and regulators satisfied. Process water picks up metals, sulphates, and fine solids as ore is washed and milled. Left alone, that mix blocks reuse and discharge, communities worry, permits tighten, and costs rise. Plants need a reliable on-site way to return clean water to the circuit.

Some sites pay to haul waste off site, but costs climb and you lose control. Ponds can help for a time, then load builds and performance fades. On-site treatment changes the maths with big savings on trucking, direct control over outcomes, high recovery, and the ability to reuse water across the plant with a near closed-loop setup. With demand for lithium and battery metals rising, strong treatment keeps margins healthy and output consistent.

When ore meets water, metals and sulphates leach into solution, pH slides, and suspended solids climb. That mix becomes mining-influenced water (MIW).

Common risks include:

Any one can push you out of spec and force treatment or controlled disposal.

Untreated flows create a long list of headaches: acid runoff from pits and tailings, groundwater impacts, saline brines that foul equipment, and aquifer toxification. Many mines sit in dry regions where fresh water is already scarce. Recycling reduces intake and friction with neighbours. You can treat and reuse water for process, dust suppression, irrigation, and in some cases potable supply (local rules decide the final step).

Alkalinity protects infrastructure when it’s balanced—but excess alkalinity can drive scale and damage. ChemREADY can help evaluate your water chemistry and identify whether alkalinity is within the optimal range.

Target the main sources first—process water, contact water, and stormwater that touches ore or tailings. The goals are consistent: remove metals and suspended solids, cut reagents and colour, and bring pH back into the safe band. That calls for the right chemicals and the right filters.

Raising pH pushes dissolved metals out of solution. Metal ions meet hydroxide and form dense, insoluble solids that settle and press well. Many plants aim for pH ≥ 8 before the next step.

Fine particles rarely settle on their own. Coagulants neutralise charge and flocculants link fines into large, strong floc. ChemREADY’s FlocREADY grades suit mineral streams and keep polymer spend under control.

Some feeds need more help:

Chemistry sets the table; mechanical steps finish the job. Typical kit includes:

A wider programme might add Biological Processes, Desalination, Clarification, Evaporation and Crystallisation, Disinfection, Ion Exchange, Membrane Separation, Package Plants, Sludge Dewatering and Handling, and Zero Liquid Discharge.

High alkalinity is a common driver of calcium carbonate scaling that restricts flow and damages equipment. ChemREADY helps facilities control alkalinity and prevent scale before it becomes a costly problem.

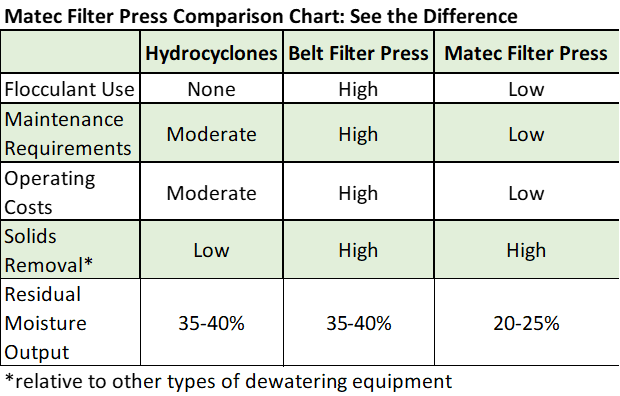

Workhorse units for classification, fines recovery, and dewatering. They have no moving parts, need no chemicals at the unit, offer high throughput in a small footprint, and make great pre-treatment before a press. On their own they rarely deliver final solids, so pair with a high-efficiency filter press for full capture.

Fast to start and stop with a modest footprint and low entry cost. Two belts squeeze slurry through gravity and pressure zones to produce a “cake” that’s easy to handle. Over time, high polymer dose and frequent belt changes add cost, and cake solids often need further work before dry stacking.

The gold standard for high-quality dewatering. A feed pump drives slurry into plate chambers; filtrate exits while solids build into a firm cake. Filter presses deliver strong energy performance, often around one-sixth the operating cost of a belt press or centrifuge. Low-pressure units exist, but many mines step up to high-pressure builds for tougher duties.

ChemREADY supplies Matec high-pressure presses for mine tailings. They operate up to 30 bar, handle dense, abrasive slurries, use little polymer, require less maintenance, and produce stable, stackable cakes that suit dry stacking. Key features include automatic cloth washing with open filtrate design, remote monitoring and live support, High Pressure Technology (HPT) over 30 bar, and clean, reliable cake discharge.

Washed aggregates and fines create heavy loads. FlocREADY chemistries and the Matec press platform cut turbidity and raise recovery so you get back to spec and back to production.

We run clear ROI models for trucking, ponds, and on-site treatment. Inputs are simple—flow, solids, power, labour, and polymer—and we return a one-page view with payback and risk.

We bring chemicals, equipment, and service under one roof: site survey and jar tests, pilot loops where needed, full programme setup with KPIs and training, and ongoing optimisation through season and ore change. No one-size bundle—data first, results that stick. Talk with our team if you need help with mining wastewater treatment. You’ll get a plan that fits your ore, your water, and your budget.

From alkalinity control to full water treatment programs, ChemREADY supports industrial and municipal systems with practical chemistry solutions and expert guidance.