Boilers and cooling towers rely on consistent water treatment to stay operational. When used effectively, ultra-concentrated products allow for a more efficient water treatment process, enabling:

That’s why more and more plant managers are turning to ultra-concentrated products and chemicals to help optimize their boiler and cooling tower water treatment systems. By improving such a key process, you can help keep downtime to a minimum and make sure that your business stays profitable.

An ultra-concentrated product has the maximum concentration of active ingredients possible, while still remaining fluid enough for practical application. Theoretically, a product could be 100% active ingredients, but this would make it too thick to apply effectively.

In reality, ultra-concentrated products typically have 90-98 percent active ingredients. When formulated properly, these products can perform as well as—or even better than—standard products. Common examples in everyday life include laundry detergent pods and highly concentrated soap mixes.

When you do not use ultra-concentrated chemicals, you’re often stuck with large, bulky containers that are difficult and expensive to move. A major reason is the over-reliance on water as a filler in standard products.

Because these products are water-heavy, they are costly to ship and can cause major spills or leaks if mishandled. The water treatment industry often sees large, heavy drums of chemical mixtures that are both expensive to transport and cumbersome to store onsite. Moving these containers usually requires heavy-duty machinery, increasing the risk of workplace accidents.

You must also comply with local regulations and fire department ordinances when storing large drums. Standard products can include binding agents and come in unsustainable packaging, complicating disposal. Their larger container size often means product goes to waste when you can’t fully empty the drum.

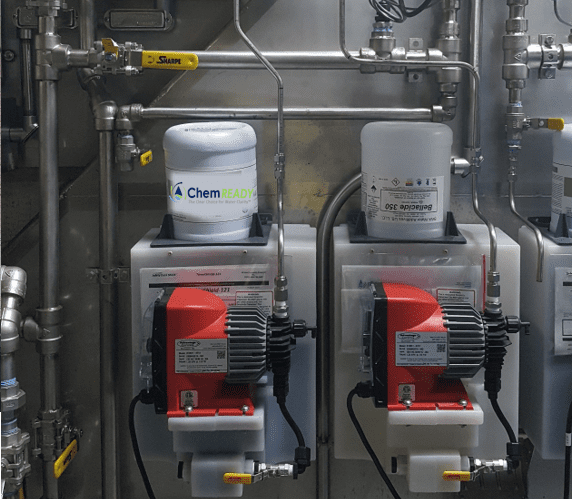

If you want a more efficient water treatment program, ultra-concentrated products are an excellent solution. They come in small, 1-gallon containers that are easy for anyone to lift without specialized equipment like forklifts. This not only reduces risk of injury but also minimizes chances of forklift-related accidents.

Because they contain fewer fillers, ultra-concentrates are more cost-effective to ship. They are also eco-friendly, making them a more sustainable choice long-term. Key environmental benefits include:

These advantages lower operating costs and help you meet environmental and safety regulations, all while keeping your boiler and cooling tower systems operating reliably.

Here at ChemREADY, we combine decades of industry experience with the best ultra-concentrated chemical technology. This approach helps us design, improve, and validate your wastewater treatment operations, creating a safer and more compliant working environment for your business.

Our ultra-concentrated, performance-enhancing products include premium antiscalants, anti-fouling agents, and corrosion inhibitors for industrial boiler, cooling tower, closed-loop, and steam-line applications. Once we identify the right chemicals for your unique system, our experts will guide you on proper dosage to ensure optimal system safety and performance.

Many of our ultra-concentrated products feature a No-Touch dispensing system, similar to an office water cooler jug. This design avoids the need to open product caps manually, reducing spillage and worker exposure. Simply invert the container onto the dispensing pin, then pump the solution into your system based on your specific needs—no chemical handling required.

If you’re looking for a trusted water treatment partner, consider ChemREADY’s Total-Service-Management™. We offer various program levels where our system experts take over the service of your boiler, cooling tower, and other water treatment equipment, ensuring maximum efficiency and compliance.

If you’d like to learn more about what chemicals to use for your own wastewater treatment, download our Water Treatment Buyers’ Guide today. By choosing ultra-concentrated products, you’ll help protect both your bottom line and the well-being of your team—while maintaining a high-performing, reliable water treatment system.

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.