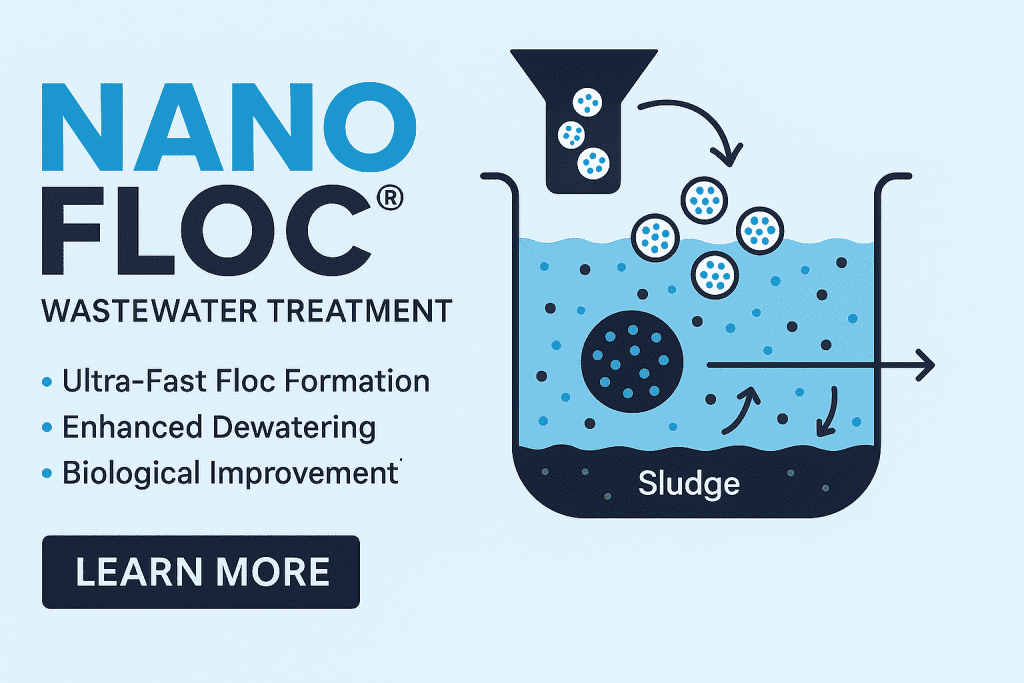

ChemREADY is your trusted North American distributor for Nanofloc®, a next-generation wastewater flocculant technology designed to deliver faster, more efficient solid-liquid separation. With Nanofloc®, water treatment facilities achieve improved turbidity reduction, reduced chemical consumption, and optimized sludge handling — all without requiring major system changes.

Nanofloc®: Advanced Chemistry. Smarter Treatment. Measurable Results.

Nanofloc® uses precision-engineered nano-scale wastewater flocculant agents that enhance charge neutralization and bridging efficiency. The result: cleaner effluent, greater process stability, and consistent compliance in both municipal and industrial systems.

Nanofloc® is designed to meet the demands of high-performance wastewater flocculant treatment across a range of industries. Its rapid settling action, low dosage requirements, and exceptional contaminant control make it the perfect solution for:

Ensure regulatory compliance, manage peak loads, and enhance clarifier performance with faster sludge settling and improved effluent quality.

Tackle organic load fluctuations and reduce sludge volumes efficiently, all while maintaining strict discharge limits.

Control suspended solids and reduce polymer demand in systems dealing with high fiber content and complex waste streams.

Improve thickening performance and reduce reloading, polymer consumption, and disposal costs with more compact sludge flocs.

Pre-condition challenging effluents to improve overall plant stability and reduce biological system stress during variable loads or shock events.

ChemREADY is proud to be the exclusive distributor of Nanofloc® in North America, providing industry-leading service alongside a cutting-edge wastewater flocculant. We deliver:

Application-specific formulations tailored to your wastewater profile and system design.

Field engineers ensure proper commissioning, training, and integration into existing systems.

Regular audits and water quality testing to optimize treatment outcomes and operational savings.

Regional stocking points ensure fast, reliable delivery and minimal downtime for your operation.