Reading Time | 15 Minutes

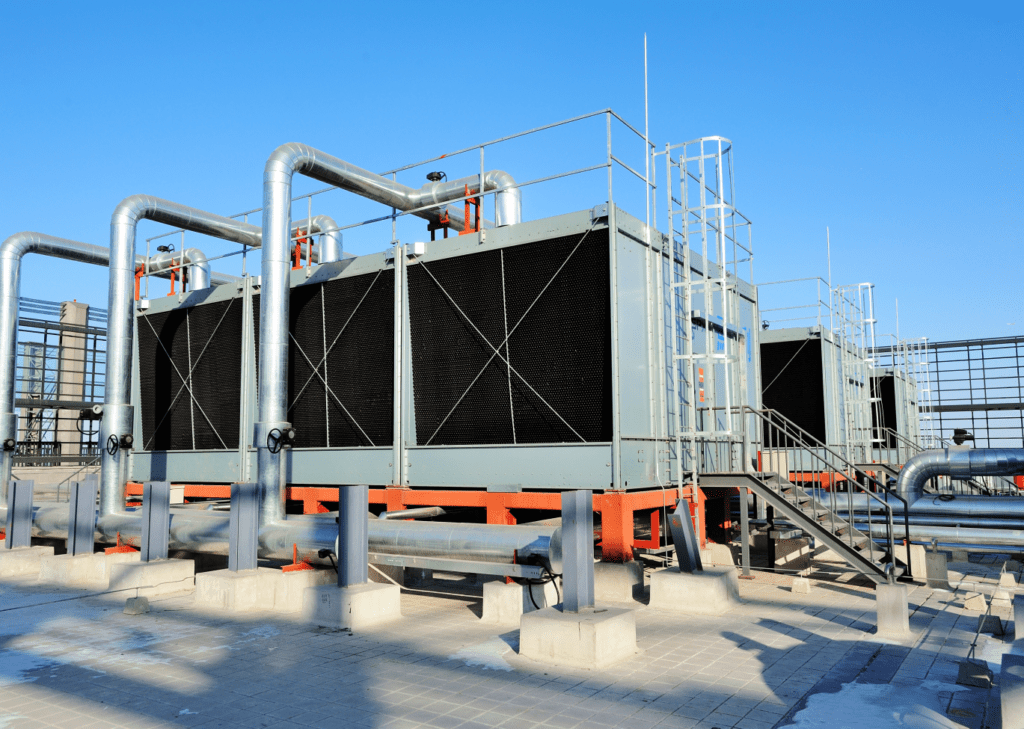

It’s the end of February, which means one thing in our world. Cooling tower season is coming back.

Right now, your tower might still be quiet. Maybe it’s been sitting idle all winter. Maybe it was drained and laid up. Maybe it’s just been running minimally in the background.

But in a few short weeks, when temperatures climb and production ramps up, that system is going to matter again. A lot.

And every spring, we see the same pattern: facilities flip the switch, assume everything is fine, and then by May they’re dealing with corrosion issues, microbiological growth, scaling, or emergency service calls.

The good news? Most of it is preventable.

Here are some of the biggest start-up mistakes we see — and what we’ve learned over the years about avoiding them.

Make sure your cooling tower is inspected, cleaned, and chemically balanced before peak demand hits.

One of the most common assumptions is that if the tower ran fine last season, it’ll run fine this season.

But a cooling tower isn’t a light fixture. It’s a living, breathing water system. And water systems change over time — especially when they sit.

Over the winter, you can get:

Even if everything looked good in October, March is a different story.

What we’ve learned: Start-up should be treated like a reset, not a restart. Inspect, verify, confirm — don’t assume.

You’d be surprised how often we open towers in the spring and find:

If no one physically looks inside the tower before start-up, you’re operating blind.

And sludge isn’t just ugly — it’s fuel. It feeds microbiological growth, reduces heat transfer efficiency, and increases chemical demand.

What we’ve learned: A visual inspection tells you more in 15 minutes than weeks of guessing later.

Another pattern we see: the tower gets turned on, but chemistry doesn’t get attention until scaling or corrosion shows up.

That’s backwards.

The first days and weeks of operation are critical. That’s when:

If conductivity controllers weren’t checked…

If feed systems weren’t verified…

If sensors drifted over winter…

You may not be feeding what you think you’re feeding.

What we’ve learned: Early chemistry control prevents mid-season emergencies.

Avoid scale, corrosion, and microbiological surprises with a verified start-up plan.

Spring start-up is one of the highest-risk periods for microbiological growth — especially if the system has had stagnant water.

Warmer temperatures + nutrients + surfaces = rapid growth potential.

Cooling towers are powerful pieces of equipment. They move large volumes of air and water. That’s why microbiological control isn’t just about efficiency — it’s about safety.

We’ve seen facilities focus heavily on scale and corrosion while overlooking biological control until a test result forces attention.

What we’ve learned: Microbiological management isn’t optional at start-up. It’s foundational.

A slightly fouled heat exchanger. A little extra scale. A mild corrosion issue. A bit more blowdown than normal. Individually, these seem manageable.

But together, they increase:

Cooling towers operate continuously once the season is in full swing. Small inefficiencies multiply quickly.

What we’ve learned: Spring is the cheapest time to correct issues. Summer is the most expensive.

This one might be the most common of all.

We get calls in late May or June that start with:

“We just turned the tower on and…”

By then:

That’s not the time to troubleshoot.

The end of winter is the window. It’s the calm before the storm — and it’s the smartest time to evaluate, inspect, clean, and confirm your treatment program is dialed in.

What we’ve learned: Preventative attention now avoids reactive chaos later.

After years of working with cooling towers across industries, here’s what consistently leads to smooth seasons:

It’s not complicated — but it does require intention.

Cooling towers don’t fail dramatically all at once. They decline gradually when small details are ignored. Start-up season is your opportunity to reset those details.

The worst time to think about cooling tower maintenance is when it’s already hot, production is on the line, and people are asking why the system isn’t performing the way it should.

Right now — at the end of February — you have leverage. You have time. You have options.

A thoughtful start-up sets the tone for the entire season.

At ChemREADY, we’ve seen what happens when systems are rushed back online without proper evaluation. We’ve also seen how smooth an entire summer can be when start-up is handled correctly from day one.

If you’re getting ready to bring your cooling tower back online, this is the moment to make sure it’s truly ready.

Let ChemREADY assess your system, confirm your chemistry, and set you up for a smooth season.