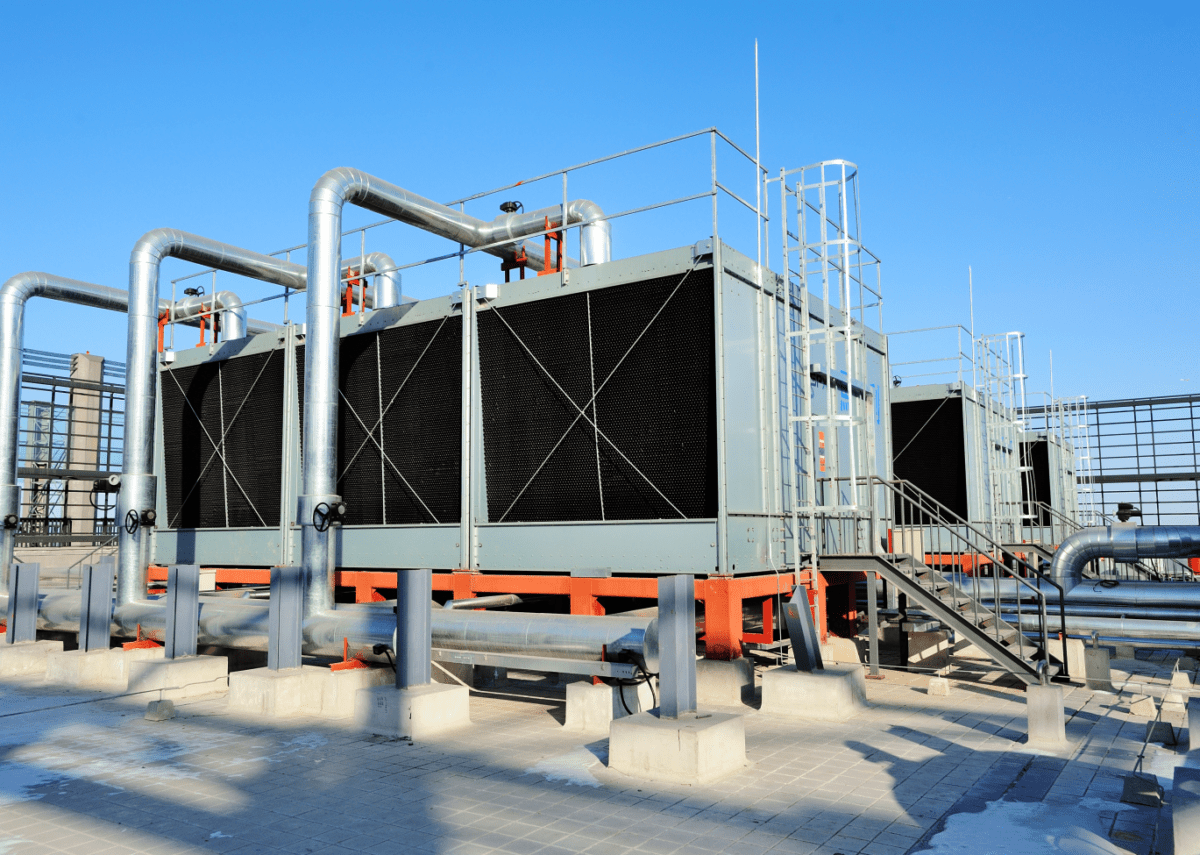

Cooling towers quietly perform a vital role in industrial operations, dissipating heat and regulating temperatures through recirculating water. Yet this circulation inevitably accumulates impurities, leading to scale, fouling, and decreased performance. Tagged Polymers for Cooling Towers are a next-generation solution, helping to disperse particles and maintain system efficiency. The key to harnessing their full potential lies in fluorescence detection, ensuring precise dosing and effective treatment.

Tagged Polymers are water-soluble molecules that prevent scale deposits and biological fouling. By keeping surfaces clean, they help maintain optimal heat exchange, reduce energy consumption, and limit downtime.

Like most treatment chemicals, correct dosage is crucial. Under-dosing wastes potential benefits, while over-dosing inflates costs and can lead to sludge buildup. Achieving this balance manually can be challenging—enter fluorescence for real-time monitoring.

Fluorescence allows users to measure the concentration of Tagged Polymers quickly. A short-wavelength light excites the added fluorescing agent, causing it to emit a specific wavelength that can be easily measured. These instant readings facilitate prompt adjustments, ensuring consistent water quality.

Because fluorescence measurement doesn’t alter water samples, you can perform repeated tests without affecting the chemistry. This makes it an excellent tool for ongoing quality checks and long-term performance tracking.

Compared to alternative methods requiring elaborate equipment or complex reagents, fluorescence offers a more straightforward approach. Field measurements can be done with portable devices, reducing both time and operational costs.

By integrating fluorescence into your cooling tower water treatment strategy, you can precisely dose Tagged Polymers to prevent scale, control microbial growth, and keep corrosion at bay. This cutting-edge yet cost-effective method offers quick, accurate, and non-destructive measurements, streamlining maintenance and safeguarding system performance.

For a closer look at how fluorescence-based solutions and Tagged Polymers can fortify your cooling tower operations, reach out to a water treatment professional. Illuminate a more efficient future—stop scaling, reduce downtime, and optimize your cooling tower’s longevity.

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.