Side stream filtration units help to keep your cooling towers operational by continually cleaning and treating the tower’s water. Since they are easy to integrate into existing systems, every plant manager should look into getting a quality side stream filter to help optimize their cooling tower’s water treatment process.

Choosing the right filter for your cooling tower will somewhat depend on the unique requirements of your specific application. These can include:

Since these can affect the requirements of your side stream filters, it is best to conduct a particle analysis on your tower’s water in order to determine exactly what you’re working with. A good filtration specialist or supplier/manufacturer will be able to help with this.

Once you know the water treatment requirements of your cooling tower, you are ready to choose a side stream filter. The key considerations to be aware of when choosing a filter are particle removal size, energy costs, modularity and backwash needs/costs.

Side stream filtration is a non-destructive water treatment process for cooling towers that does not disrupt the operations of the tower. With a side stream filtration unit, you can effectively and efficiently remove particulate from the tower’s circulating water without having to completely remove the water supply from the system.

In this way, side stream filters operate a bit differently than other mechanical water treatment methods like a filter press or clarifier. Side stream filters continually work to keep your tower’s water clean rather than waiting to treat the water until once it has become too dirty for safe operations, allowing you to keep unnecessary downtime to a minimum.

This is especially important for cooling towers as their water supply is regularly polluted from drift contamination. Bacteria, dust, human hair and airborne process waste – anything that’s in the surrounding environment – can be an issue. Since these harmful particles can and will make their way into the cooling tower, side stream filters ensure that they are filtered out in a timely fashion and before they can become a bigger problem.

In fact, side stream filtration can help to mitigate risk for the top five cooling tower problems:

That’s because side stream filtration effectively removes the root causes of these issues: particle buildup. Side stream filters remove any suspended solids, organic material and silt particles in your tower’s water, keeping your risk of fouling and biological growth to a minimum. This further leads to better scale, corrosion, and foam control.

By mitigating these risks, your heat transfer surfaces stay free of inefficiency-causing buildup and the internal components of your tower stay as healthy as possible. That way, you end up with a more reliable, higher-performing and highly efficient cooling tower with the longest service life possible.

Particle Removal Size

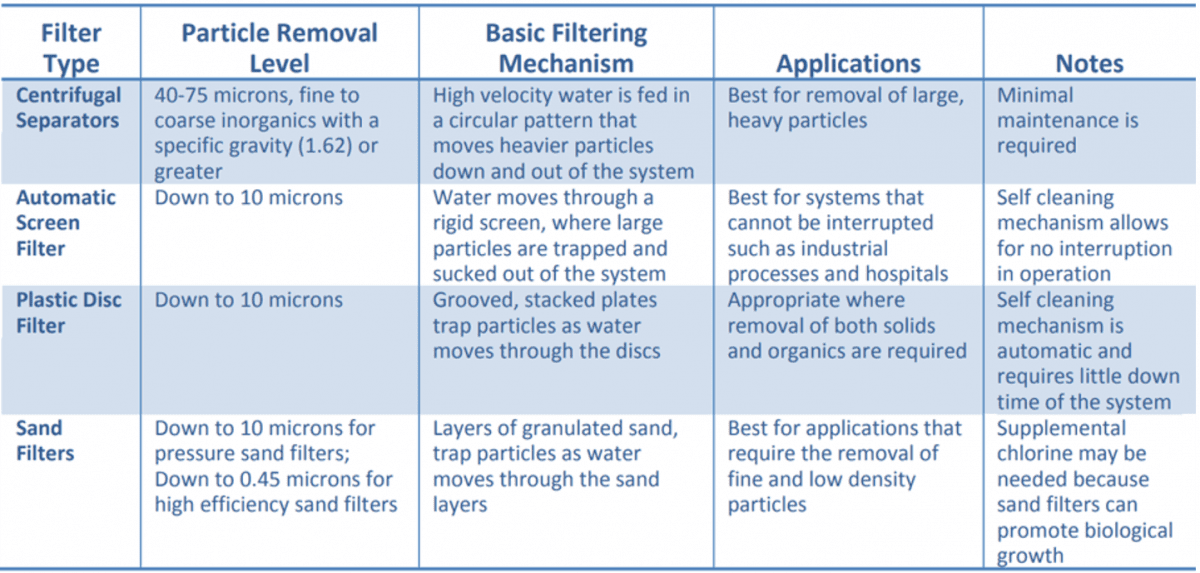

Probably the most important characteristic of your side stream filtration unit is the size of the particles that it can filter out. Generally, the ability to filter out smaller particulate is better. That’s because ultra-fine particulate, especially below 10 microns, is a leading cause of cooling tower issues. Table 1 below shows the particle removal levels of the most common filter types.

As you can see, most side stream filters can’t remove particles below 10 microns, meaning that ultra-fine particulate will stay around in the tower’s water supply no matter how many times you run the water through the filter. Most particle analyses show that more than 90% of cooling tower water contaminants are in the 0.5-2 micron range, so not being able to filter them out is a major stumbling block. This ultra-fine particulate will gradually build up on critical heat transfer surfaces and clog the tower’s internal components, leading to short-term inefficiencies and the eventual breakdown of your system.

That’s why, if your particle analysis reveals that you have ultra-fine particulate in your water (most do), then you should choose a high-efficiency side stream filtration unit. High-efficiency sand filters can reliably remove particles down to 0.45 microns, meaning that you will be able to catch those contaminants that fall between 0.5-2 microns.

Energy Costs

While the end goal of keeping your water clean is paramount, you will still want to make sure that you keep costs down as much as possible without interfering with the performance of your filter. Typically, filters that require a significant amount of continual pressure and/or that have to stay running 24 hours a day will have the highest energy costs. In that way, centrifugal separators are going to be one of your most expensive options in the long run.

Modularity

Filters with modular designs offer great benefits to plant managers and process technicians alike. Compact, modular designs offer simple, crane-free installation and can be more easily maneuvered around your plant, fitting through a standard door frame. Routine maintenance is also streamlined with modular designs, allowing you to perform maintenance and replace any parts quickly and efficiently.

Additionally, you can easily change out, add or remove modular side stream filtration units without needing any downtime.

Backwash Needs/Cost

For most side stream filters, some amount of backwash is required. Backwashing removes debris and particles that build up on your filter during the filtration process.

To ensure proper filter maintenance, backwashing is activated either when a sensor notices a pressure difference across the filter, indicating a clog, or simply during regular intervals. Naturally, the higher the backwash requirements of the filter, the more you will incur costs during the life of the filter.

Here at ChemREADY, we specialize in offering a complete water treatment solution for cooling towers. Beyond our chemical water treatment products and particle analysis services, our professional-grade high-efficiency system filters provide the best continual water treatment solution for cooling towers.

These modular, cost-efficient filters can be used with any cooling tower system to optimize your water treatment and keep your equipment running at peak efficiency. Other benefits of our high-efficiency side stream filters include:

ChemREADY’s filters offer the flexibility and redundancy plant managers need to ensure clean cooling tower operations. ChemREADY offers two base units: the CT 70, 70 gallon per min, for larger industrial systems and the CT 30, 30 gallon per min, for smaller commercial applications.

With our chemical expertise and mechanical filtration knowledge, ChemREADY offers total water treatment assistance for industrial processes of any kind.

In addition to specially formulated coagulants, we also offer various pretreatment chemical products, such as pH adjusters, corrosion inhibitors, and biocides. From mining operations and concrete production to industrial boilers and cooling towers, ChemREADY has the expertise and chemicals that you need to keep your systems running.

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.