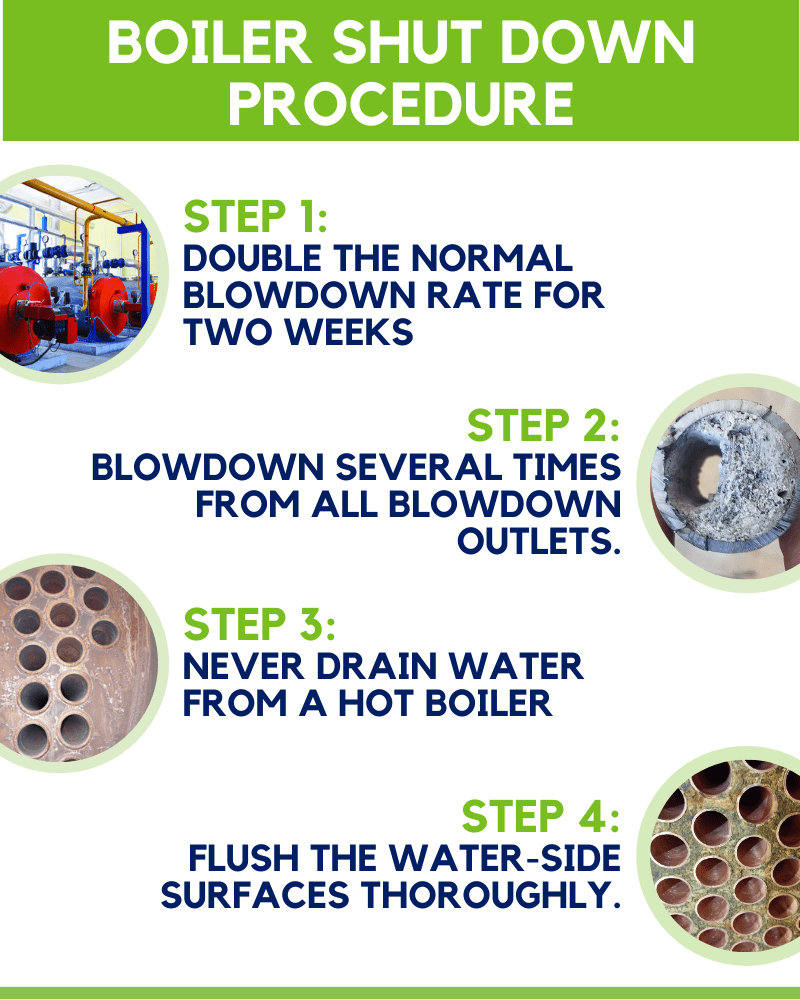

Boiler shutdown is a critical process that, if done incorrectly, can lead to warping, corrosion, leaks, and costly repairs. Many boiler failures occur due to improper lay-up procedures, exposing internal components to moisture and oxygen, which accelerates corrosion.

To prevent damage, boilers should be shut down using the correct method and protected during idle periods. This guide provides step-by-step boiler shutdown procedures for wet and dry storage to help reduce downtime and extend equipment life.

Boilers should be properly stored when out of service to prevent corrosion and system degradation. There are two main methods for boiler lay-up:

This method removes moisture from the boiler and prevents tube wear and corrosion.

The wet method fills the boiler with treated water, preventing oxygen contact and corrosion.

For boiler treatment, we recommend our Boiler Aid series, which contains a blend of:

✅ Complex polyphosphates for scale control

✅ Dispersants to keep surfaces clean

✅ Sludge conditioners to enhance removal

Top Recommended Products:

🔹 Explore ChemREADY Boiler Treatment Solutions

At ChemREADY, we provide comprehensive boiler water treatment solutions to extend boiler life, reduce corrosion, and improve efficiency. Our services include:

✅ Site surveys for system evaluation

✅ Total Service Management for boiler maintenance

✅ Custom boiler treatment programs

✅ Expert recommendations for boiler shutdown and lay-up procedures

🔹 Learn More: ChemREADY Boiler Water Treatment Services

Improper shutdown can cause warping, leaks, scale buildup, and corrosion, leading to expensive repairs and system failures.

The dry lay-up method is best for long-term storage, while the wet lay-up method is better for short-term storage when quick startup is needed.

Use oxygen scavengers like BOILER AID 385 or 386, keep the boiler completely dry or filled with treated water, and seal all openings to prevent moisture intrusion.

For dry storage, inspect every two months. For wet storage, test water quality every one to two weeks.

We offer site surveys, customized boiler treatment solutions, and total service management programs to ensure optimal boiler performance.

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.