Reverse Osmosis (RO) for ANSI/AAMI ST108

Water problems can stop sterile processing.

Minerals and other contaminants can cause spots, scale, and failed results.

Reverse Osmosis (RO) is a key step for ST108 Critical Water

RO helps remove dissolved salts and other contaminants so your water can meet tight ST108 targets.

What RO Does

Reverse Osmosis is a membrane system. It uses pressure to push water through a special filter.

Dissolved Salts

Organic Molecules

Larger Particles

Is RO required for ST108?

ST108 focuses on water quality results, not one exact machine. But here’s the practical truth: If your process needs Critical Water, RO is one of the most common and effective ways to reach the high purity levels many facilities need.

Our RO Products

CGD 14-44: Reverse Osmosis System

1,800 – 7,200 Gallons Per Day, compact system for small-scale applications., an affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint make this the perfect system for your application.

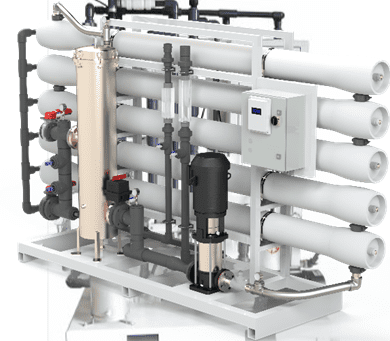

PG 24-44 Reverse Osmosis System

5,000 – 10,000 Gallons Per Day, high-efficiency system for medium-scale needs. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

PGI 188 Reverse Osmosis System

144,000 Gallons Per Day, advanced system for maximum water purity. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

PGI 28-48 Reverse Osmosis System

23,080 – 46,000 Gallons Per Day, industrial-grade system for large-scale operations, An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

PGI 68-158 Reverse Osmosis System

69,000 – 172,500 Gallons Per Day, robust system for extensive industrial use. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

Common signs you need RO

RO is a strong fit when you have:

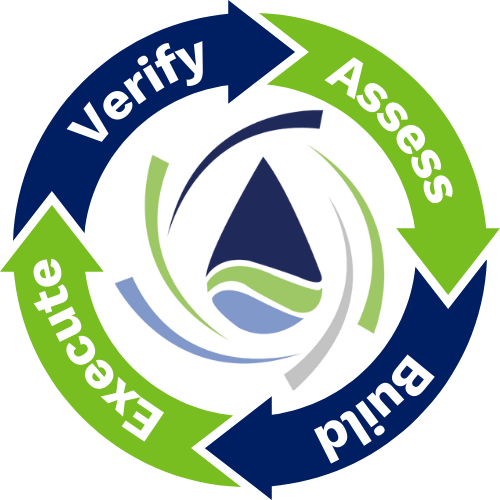

How it Works

Spots or Film After Rinsing

We evaluate your rinse water quality to identify what’s causing spotting, residue, or film. This helps determine whether minerals, contaminants, or system issues are affecting final-rinse performance.

Scale Buildup in Washers or Sterilizers

We assess hardness, alkalinity, and other scaling factors to pinpoint the source of buildup. This allows us to recommend the right treatment steps to protect equipment and maintain reliable cleaning results.

Mineral-Heavy Incoming Water

We review your incoming water supply to understand which minerals are driving quality problems. From there, we determine the treatment level needed to stabilize your system and meet performance targets.

Unstable Water Results You Can’t Control

We analyze fluctuations in water quality and identify the conditions causing inconsistency. Our findings help you regain control through proper testing, monitoring, and appropriately sized treatment solutions.

Why ChemREADY RO systems

With the right RO system, you can:

- Improve rinse quality

- Reduce scale and mineral problems

- Protect expensive equipment

- Build a stronger ST108 Critical Water program

Choose your RO system

We’ll help you size the right model for your flow rate, demand, and water quality goals.

NSF Certified Chemicals

Our formulations meet NSF safety standards to protect your people and your equipment.

50+ Years of Expertise

Backed by decades of industry experience and a proven track record of results.

Regional Expertise

Serving facilities across the midwest with responsive, local water treatment support.

Get ChemREADY’s Free WMP Review

Our Services

Closed Loop Water Treatment

Closed loops feed your heat exchangers too. Explore our Closed Loop Water Treatment and Glycol Solutions to stop corrosion before it reaches your boiler.

Cooling Tower Solutions

Your steam system isn’t the only one that needs protection. Keep your cooling water clean and balanced with our Cooling Tower Treatment Programs.

Filtration Solutions

For maximum reliability, combine your boiler program with Filtration Solutions to remove rust and debris before they enter your feedwater system