Matec’s Concrete Water Recycling (CWR) plants remove solids from water derived from washing ready mix trucks, cement mixers, pumps, and buckets. When combined with Disol 5000 (grease trap), the plant also solves the problem of water derived from washing wheels and tires off trucks exiting construction sites.

Matec’s Concrete Water Recycling Plants are designed to recover and re-use washing water, by automatically filtering out the solids without using chemical additives. It will also provide a manageable solid without the need of cleaning out weir pits.

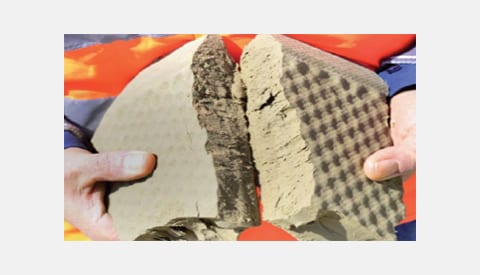

CWR allows you to recover your aggregates (sand and stone using a screw separator) which can be further separated if desired (using a dewatering screen) to provide a sand product and a stone product. The remaining cement slurry water is sent to the filter press for filtration and dewatering returning approximately 90% – 95% of your water back for reuse.

Using Matec Concrete Water Recycling Plants, you’ll be able to handle return concrete without having to dump, let dry, and then crush the material. Any sand and stone can be recovered immediately. You can even customize the separation between sand, stone, and water. This plant allows for single use handling. Ready mix trucks would be able to instantly discharge and return back to production in a more efficient manner. Using a CWR plant will give operations the capability to wash 1-4 trucks at a time and can be enclosed for cold weather operation and lower infrastructure costs.

The plant also makes handling water and eliminates the settling of solids in the pits. This improves operations and the bottom line by not having the labor and equipment needed to clean out the pits.

You’ll also be able to control the pH of the water, something that is a growing issue with regulatory agencies and the EPA. Furthermore, the system can be close looped to start saving on purchasing water from outside sources. Given that water is a growing premium with an out break of droughts and fires across the country, this provides a sustainable and cost-efficient solution.

Our concrete water recycling plants aren’t just for ready mix operations. Anything dealing with concrete or ready mix can use this system from concrete cutting, precast, pipe lining, anything ready mix related, it can handle it all. Anything involving washout slurry, a CWR plant is your best solution.

Speak with one of our sales technicians for more information.